A record 62 million tons of e-waste were generated worldwide in 2022 – enough to fill a line of 1.5 million massive 40-ton dump trucks that would wrap the Earth at the equator.

Less than a quarter (22.3%) of that e-waste was recycled. While that percentage is growing, e-waste generation is growing far faster. From 2010 to 2022, the recycling of e-waste rose from 8 billion kg to 13.8 billion kg, while total e-waste grew from 34 billion kg to 62 billion kg.

Simply put: The amount of e-waste generation outpaced the amount recycled by a factor of five. Annual e-waste is projected to reach 82 million tons by 2030.

The figures come from the fourth edition of the respected Global eWaste Monitor report, released in March 2024 by the United Nations Institute for Training and Research and the International Telecommunication Union. The report highlights the increasing e-waste problem due to rising demand for technology products, short product life cycles, and slow adoption of e-waste regulations.

These trends underscore the critical role of the ITAD industry in addressing modern business technology challenges and building systems that support a robust circular economy for technology.

Given the exponential growth in e-waste, SK tes is at the forefront of tackling these challenges, investing in technology lifecycle solutions.

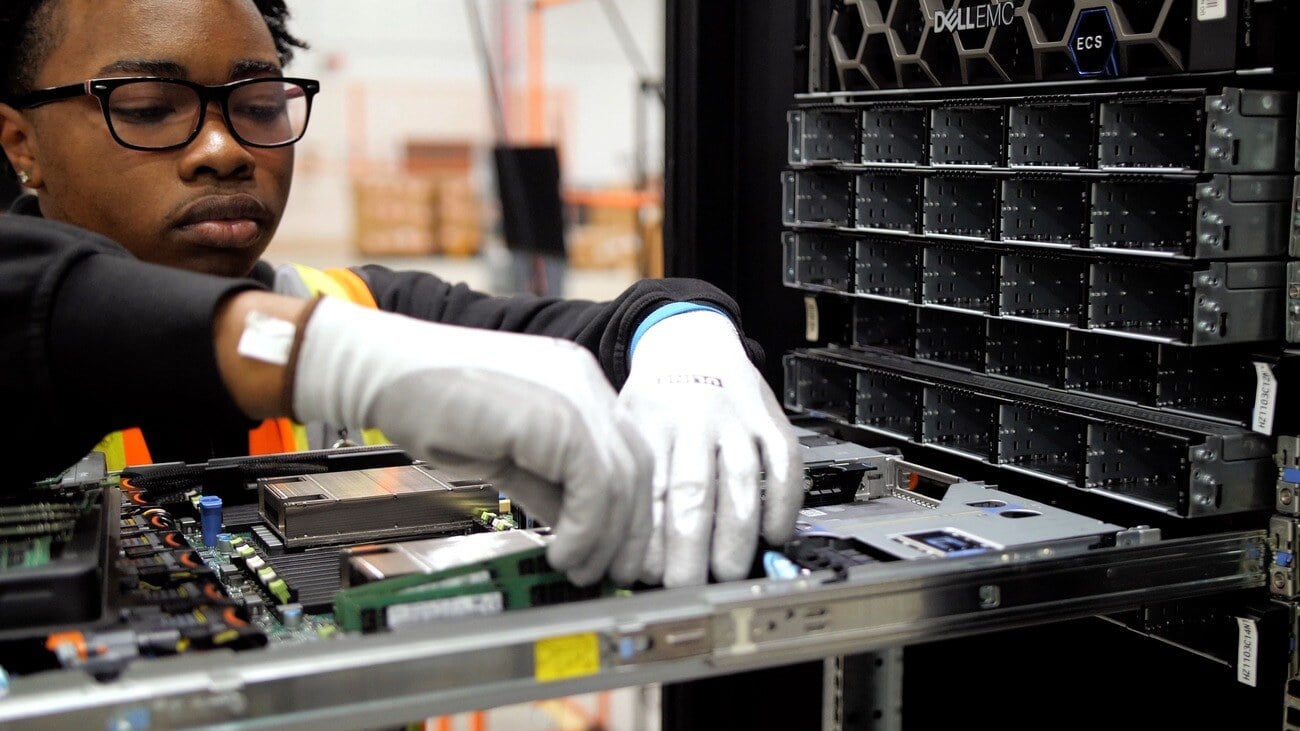

SK tes continues to meet this challenge. In the past year, SK tes processed 101.8 million kg of technology equipment, maintaining progress toward its “Decade of Difference” commitment to recycle 1 billion kg by 2030. The company is scaling up with investments in new facilities, expanding operations in Recklinghausen, Germany, and Seattle, USA, and launching a flagship ITAD site in Washington, DC, to serve hyperscale data centers supporting the U.S. government.

The global nature of e-waste poses two major challenges. First, ITAD providers must be capable of delivering standardized services worldwide while navigating complex and evolving compliance requirements. Second, they must offer transparent sustainability reporting, ensuring clients have insights into their environmental impact.

SK tes has the global reach to address these needs, with ITAD services in over 100 countries through its 40+ facilities across 20+ nations—making it the largest global network of owned and operated IT and data center equipment disposition facilities. SK tes is expanding further, with new commitments in battery recycling in Japan and a cutting-edge ITAD processing site in Hanoi, Vietnam. Recently, SK tes helped a multinational client securely process 90,000 IT assets within 12 months.

To ensure transparency in sustainability outcomes, SK tes provides clients with standardized global reporting, detailing chain of custody and environmental impact metrics. The company operates with the highest ESG standards, assisting clients in meeting sustainability goals.

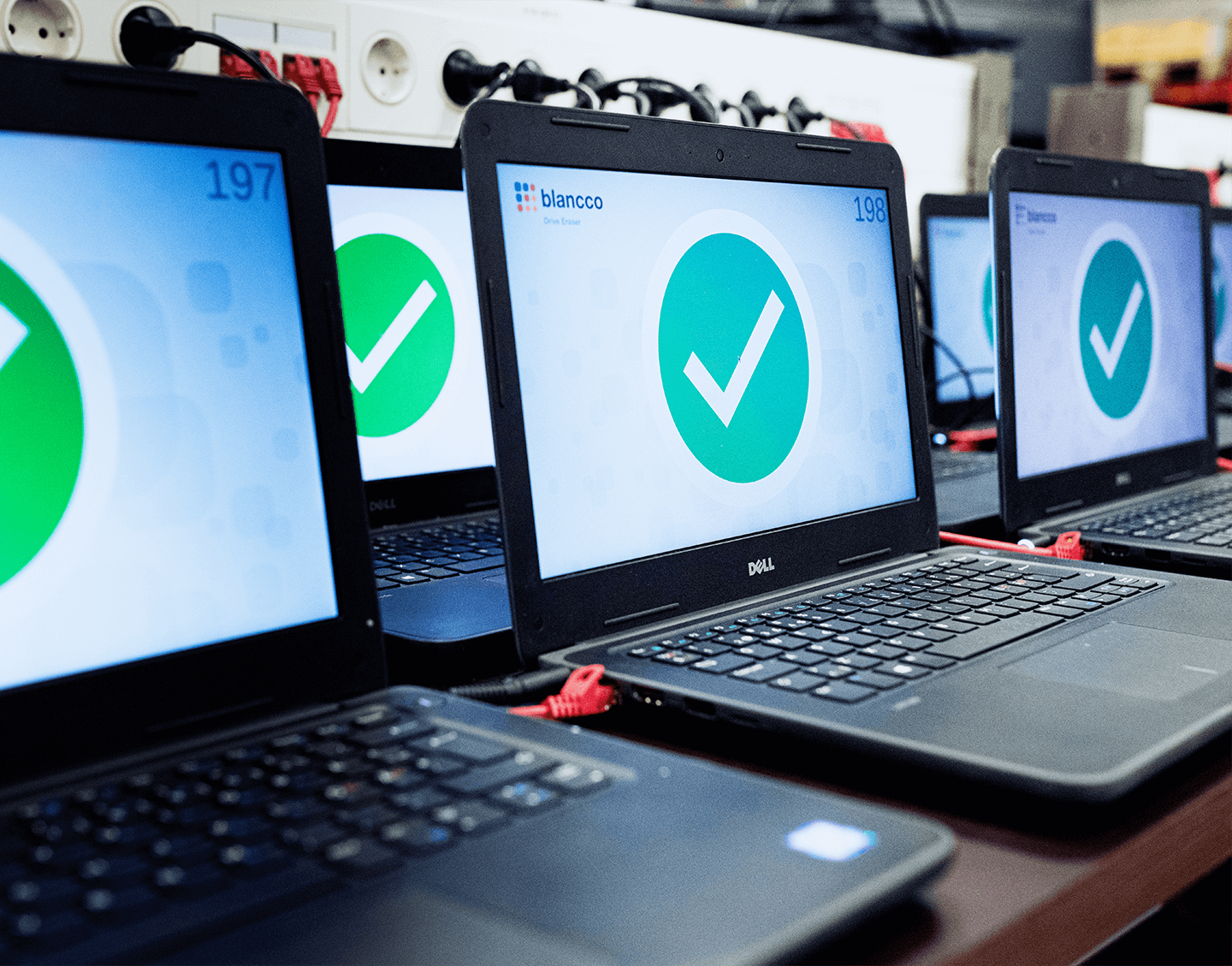

Innovation is key to addressing the e-waste crisis. ITAD companies must go beyond traditional processes and proactively maximize the reuse of assets, parts, and materials. SK tes works with clients to optimize financial, environmental, and social benefits—whether through recycling, redeploying assets internally, or reselling them to extend their lifecycle. These solutions help businesses reduce costs while minimizing the environmental impact of manufacturing new devices.

Clients consistently recognize SK tes for exceeding expectations. A global pharma client stated: “SK tes masters our processes 100% and applies them in our interests. SK tes is a real partner.” A global OEM noted: “SK tes is a great partner to work with because of high responsiveness, flexibility, competitiveness, ownership, and collaboration.”

As digital transformation accelerates and e-waste continues to grow, SK tes innovations help businesses meet asset management needs while protecting the planet for future generations.

Featured article:

Accepting the Global E-waste Challenge: How Businesses Can Play Their Part