Closing the Loop in Technology - Extend the Lifeline of Your IT Assets

The circular economy promotes advanced recycling practices that enable the capture and reuse of materials in new products, including IT assets and technology devices.

This approach reduces waste and conserves natural resources by continuously cycling materials back into the production process. The goal is to ensure that "everything old becomes new again," transforming discarded items into valuable inputs for new manufacturing.

By reintegrating recycled materials into the supply chain, companies and technology manufacturers can minimize their environmental footprint, reduce costs associated with raw material procurement, and contribute to a more sustainable future.

This holistic approach to IT asset management is crucial for addressing environmental challenges and fostering a resilient circular economy.

Benefits of Reusing and Recycling Technology Assets

Advanced recycling techniques and repurposing technology assets help close the loop in the technology value chain. Here are six benefits for electronics manufacturers and businesses:

1. Recovering Essential Materials

Recycled tech devices contain valuable components like metals (gold, silver, copper), plastics, and rare earth elements. Reclaiming these materials reduces dependency on virgin resources and mitigates the impacts of mining.

2. Mitigating E-Waste

Refurbishing, remanufacturing, or recovering materials from outdated IT assets helps reduce e-waste, decreasing pollution and toxic hazards.

3. Cutting Production Costs

Using recycled materials in production can lead to cost savings, especially when raw materials are scarce or expensive.

4. Reducing Carbon Emissions

Recycling and reusing components lower the carbon footprint associated with raw material extraction, processing, and transportation, supporting sustainability initiatives.

5. Prolonging Product Lifespan

Refurbishing or upgrading devices extends their lifespan, reducing the need for frequent new production and promoting sustainable manufacturing.

6. Advancing ESG and Sustainability Reporting

Using recycled materials demonstrates a commitment to sustainability, helping companies meet environmental, social, and governance (ESG) goals and improve transparency in sustainability reporting.

Close the Loop in Technology Manufacturing [Infographic]

- Technology chain framework and crucial steps in the process

- IT asset value recovery and its role in the technology lifecycle

- Where to recycle and reintegrate used materials and IT components

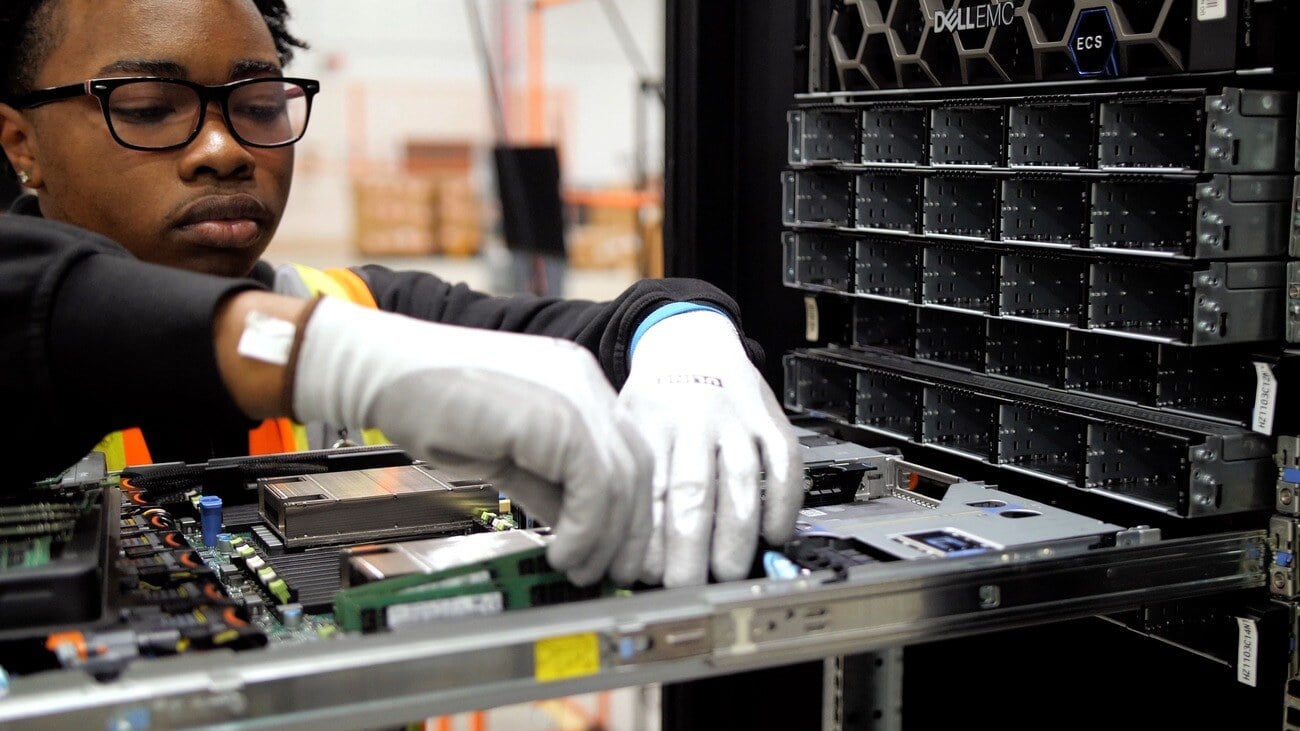

SK tes ITAD and Electronics Recycling Services

We provide comprehensive IT Asset Disposition and electronics recycling services tailored for manufacturers and businesses. Our services include secure data destruction, eco-friendly recycling for environmental compliance, IT equipment refurbishment, and data center decommissioning to extend the life of your IT assets.

Explore our ITAD services, E-waste recycling solutions, or contact us to discuss your project today.